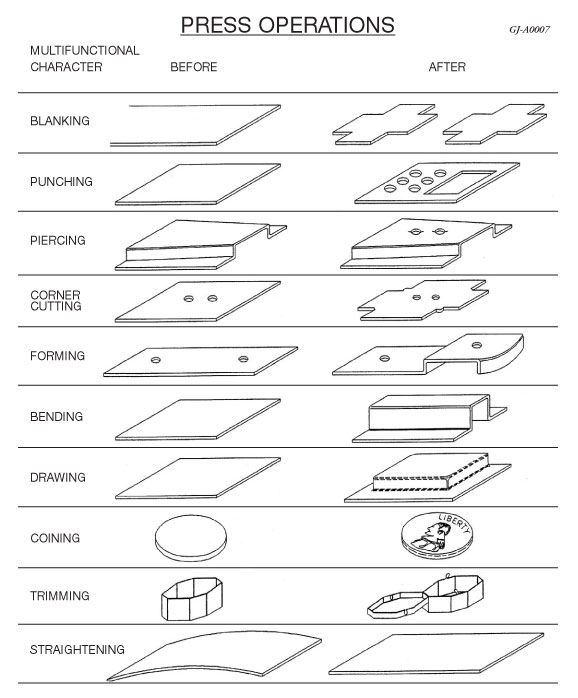

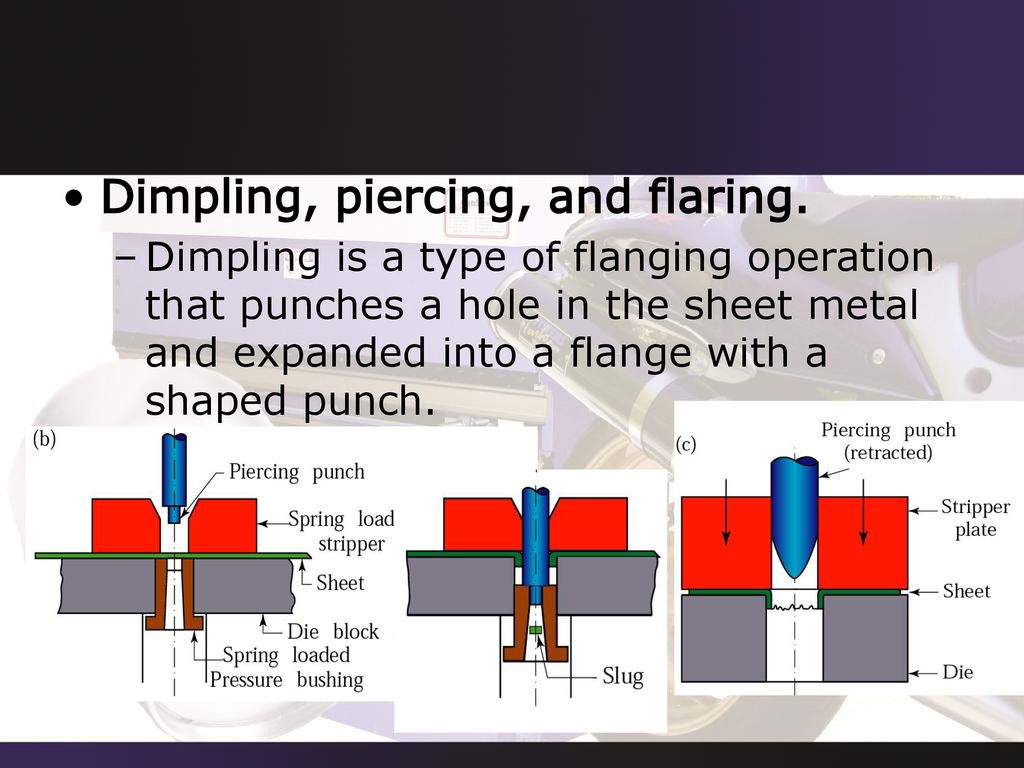

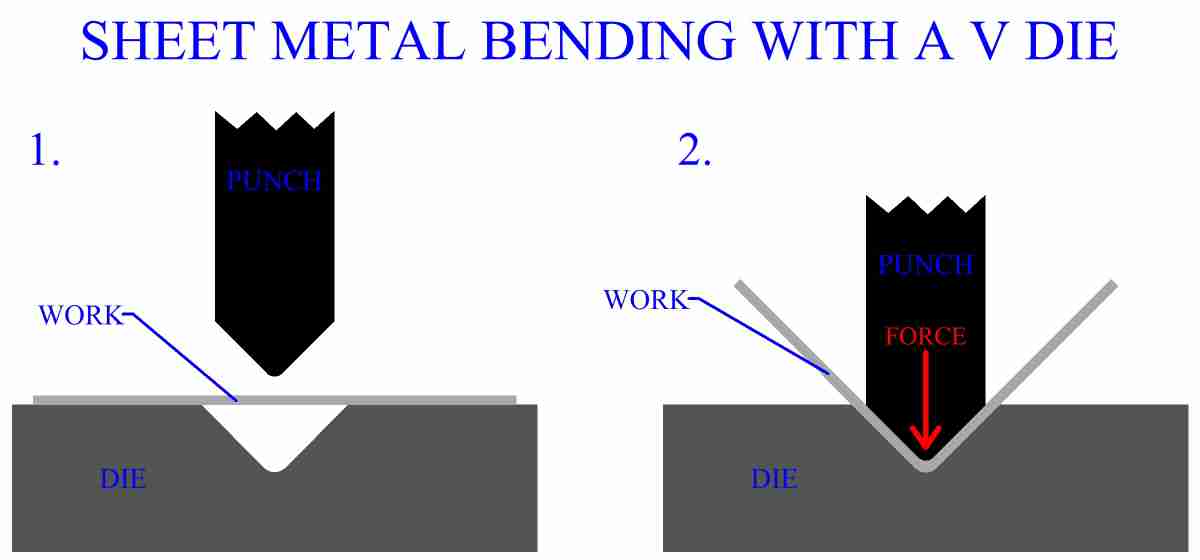

This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part or could occur through a.

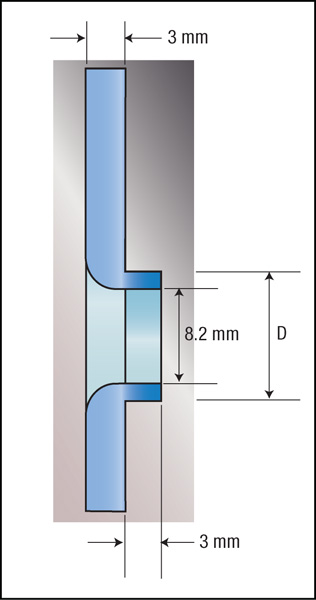

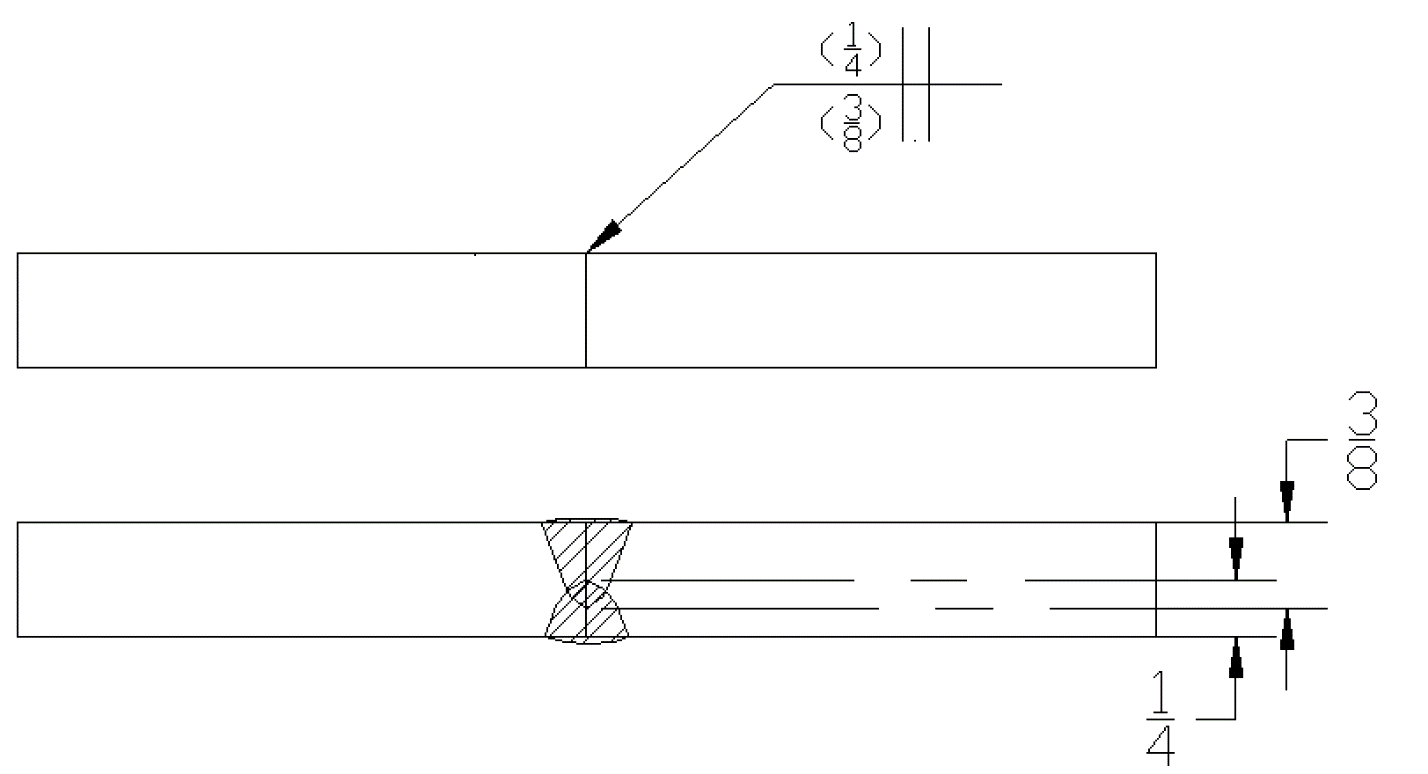

Flaring operation in sheet metal.

An elasto plastic incremental finite element computer code based on an updated lagrangian formulation was developed to simulate the flaring and nosing processes of a metal tube in the asisymmetric condition.

It s also used on seat belt retractors antilock brake system cartridges and swivel joints.

Calculate the required force to deep draw a piece of sheet metal based on the drawing ratio sheet thickness and the ultimate tensile strength of the material.

In swaging and flaring material from a post or cylinder is moved outward or inward radially to capture an edge or rim.

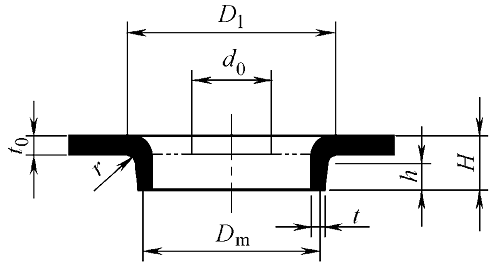

Forming a sheet metal blank into the shape required by design is initially performed in a draw die.

The extended r min technique was used to treat the elastic plastic stress state and to solve contact problems at the tool metal interface.

Instruction video for ram sheet metal unit.

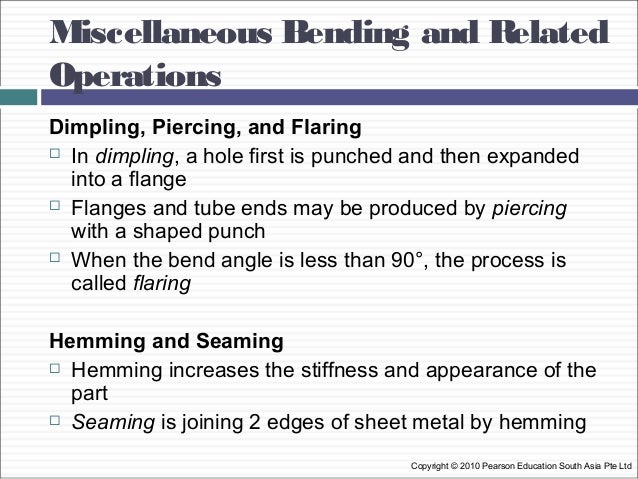

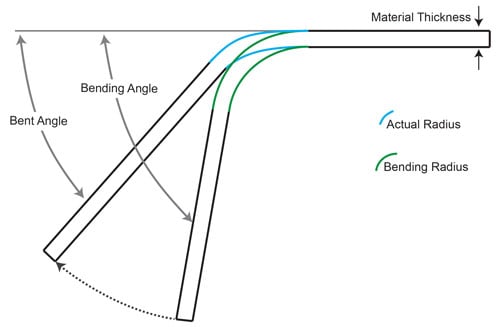

Flanging metal is the act of swiping sheet metal in a direction contrary to its previous position.

Curling is different than a tear drop hem because in a curl the edge finishes inside itself where a hem leaves the initial edge exposed.

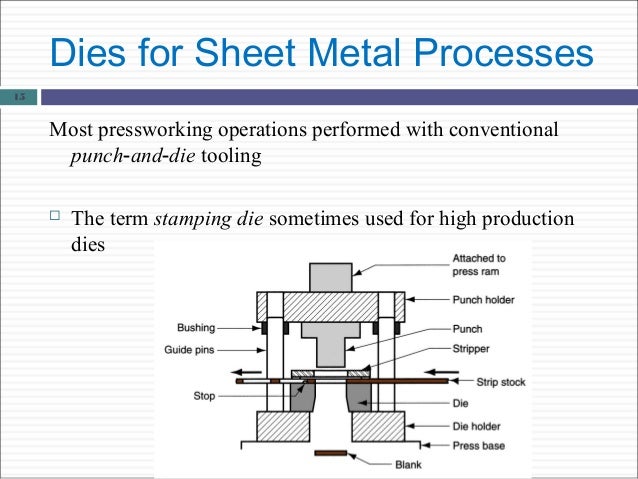

Stamping includes a variety of sheet metal forming manufacturing processes such as punching using a machine press or stamping press blanking embossing bending flanging and coining.

The drawing ratio is a measure of the severity of the drawing operation and is the ratio of the initial blank diameter to the punch diameter.

Instruction video for ram sheet metal unit.

Grease is often used to lubricate this swaging process which is also called roller swaging.

Swaging is used to attach brass pins to circuit boards.

The flaring is done with a pair of rolls that travel around the hole and are fed down into the part deforming the metal in a controlled predicted way.

A modified coulomb s friction law was introduced to treat the alternation of the sliding sticking state of friction at the contact interface.

Curling curling sheet metal is the process of adding a hollow circular roll to the edge of the sheet.

Stamping is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape.