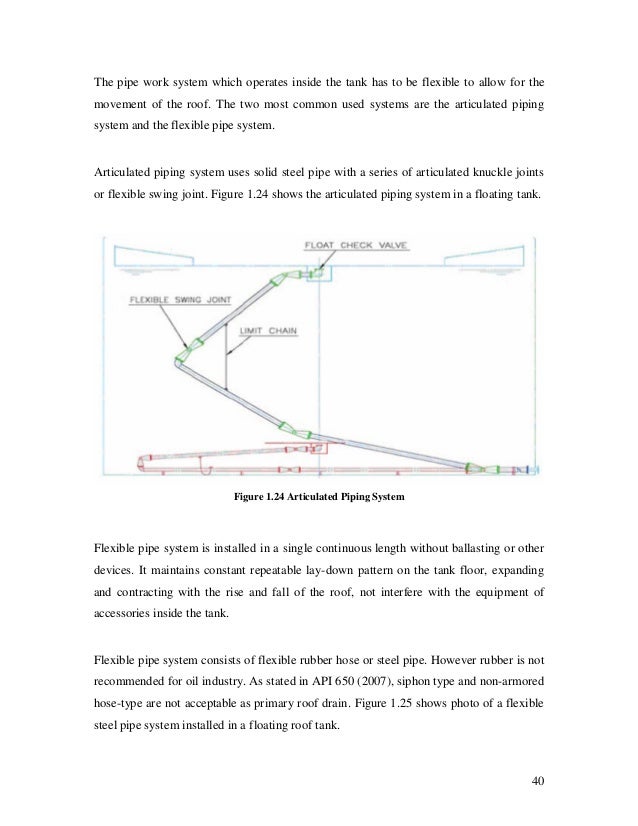

2 4 floating roof tank 11 2 4 1 history and introduction 11 2 4 2 principles of the floating roof 11 2 4 3 advantages of the floating roof storage tank 13 2 5 design data overview 13 2 6 process description and requirements 15.

Floating roof tanks ppt.

Floating roof tanks should not to be used to store products that tend to boil under atmospheric.

The roof rises and falls with the liquid level in the tank.

Usage floating roof tanks must be used to store petroleum products with flash points below 54 c 130 f or if the flash point is less than 8 c 15 f higher than the storage temperature.

Internal floating roof covered floating roof storage tank.

However they have a limitation as they can be used for small dia tanks only.

However for cfr tanks we can also use aluminum floating roof as per requirement of code as per appendix h.

The floating roof tank animation describes the working principle in the training module.

Floating roof tank allow the explosive gases in petroleum tanks to vent to atmosphere in a safe way.

An internal floating roof covered floating roof storage see red dome tank is a combination of both the cone roof or dome and the open top floating roof tank.

Various aspects of the floating roof tank working like the operation.

Today controlled gas venting in to the atmosphere is becoming more and more important due to environmental regulations.

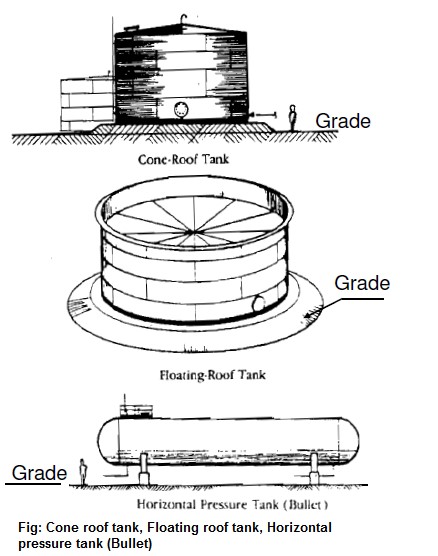

It consists of an open topped cylindrical steel shell equipped with a roof that floats on the surface of the stored liquid.

The tank has a cone roof but with the addition of an internal floating roof or pan that floats directly on the fuel surface.

Compared to fixed roof storage tanks fuel loss due to evaporation in floating roof tanks is considerably less.

28 aluminum floating roof.

Double deck are ideal for tank dia less than 17 5 m and more than 65 0mtr.

Examples of these products are gasoline and naphtha.